Project Overview

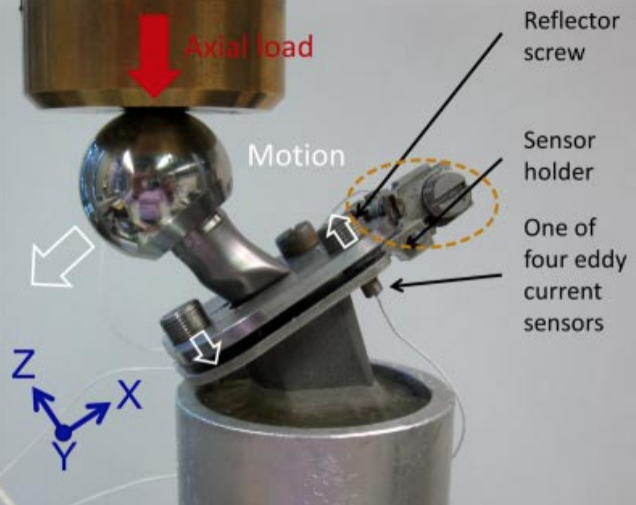

For our project, we are working on making hip implants better and safer for patients. One of the biggest issues faced in implants is the fretting corrosion of metal caused by micromotions at the taper interfaces of the prosthesis. This corrosion is affected by the way that the implant is assembled in the body. Our aim is to create a rig that will measure how a prosthesis is assembled and the amount of micromotion that occurs after applying an external axial force. This rig will then be used by surgeons for practice on assembling the hip prosthesis.

Background

In 2014, more than 7 millions Americans had some kind of artificial orthopedic implant, such as artificial hips and knees. While the implants themselves are often state-of-the-art medical designs, they aren't perfect and can lead to later complcations. Two issues with the design of the modern hip prosthesis are at the stem-neck and neck-head taper interfaces, which both bear the risk of micromotions that can result in ongoing corrosion due to removal of the passive layer and ultimately cause implant fracture1 or even chronic inflammation and necrosis of periprosthetic soft tissues2.

Baseline Goals

- Build a cheap multi-axial force sensor that can be used on a femoral head

- Successfully measure micro-motion at one of the critical taper points on the hip implant to reduce metal corrosion and resulting toxicity.

- Use a microcontroller to compute a series of implant-specific assembly force calibration points, in order to minimize taper micro-motion after the joint is used in surgery.

Reach Goals

- Build a visual feedback system which shows the direction of the applied force vector

- Integrate the inductive displacement sensor, multi-axial force sensor, and calibration computation stages on a PCB. Include a series of filters for analog de-noising data, and include an analog amplifier if necessary to boost the signal from the micro-motion displacement sensor.

- Build an automated axial load applier to allow automated reset for additional calibration points.

Learning Objectives

- Designing and integrating high-resolution sensors, as well as building a more complicated sensor from a series of cheaper sensors

- Learning to combine analog and digital signal processing to create high-accuracy systems for use in a surgeon training setting.

- Understanding the influence of micro-motion on metal corrosion, and all-around learning about the physical design of hip prostheses.